The mining industry is undergoing an extraordinary transformation worldwide driven by technology. It can respond quickly and achieve mining operations faster and more efficiently than ever before.

While some in the mining industry are slow to adopt new technologies, these advances have the potential to increase productivity, reduce long lead times and costs. Being beneficial not only to mining companies but to the entire mining sector

Robotic automation will have the biggest impact on mining technology over the next 15 years. Followed by artificial intelligence, sensors and data. This is according to a survey by The State of Play Report in Australia.

Shell and IBM have jointly developed and launched Oren, a global B2B mining services marketplace to improve productivity. The new marketplace aims to introduce shared ecommerce and digital technology services to bring efficiency into the energy development and mining markets.

If new technologies are effective, the industry can move towards a more sustainable future.

Internet of Things (IoT) & Artificial Intelligence (AI)

Hardware and software solutions are driving the growth of the global smart mining sector as well. This is done by helping to monitor the overall mining with minimal labor-intensive interference.

To make workers and the site safer, specific mining IoT applications may include adding sensors to mining equipment to monitor and communicate real-time data.

Drone technology is already used in the mining industry to increase safety in dangerous areas. Many other applications go beyond that. Progressive mining companies are building digital twins of processing plants to test different situations quickly and make mining smarter.

The IoT’s benefits for the industry lie in the underlying systems that facilitate the use of artificial intelligence (AI). Using these technologies improves reliability, while machine learning helps automate the edges of core processes.

The few systems that harness AI and machine learning still need improvement. However, they make significant savings in mining already, according to Dare Energy.

Australian mining equipment company, MineWare, has introduced a new monitoring and automation solution ‘Phoenix AI’ to optimise blasthole drill operations. It uses AI algorithms to change the force on the drill bit and rotary revolutions per minute to match the ground conditions.

According to Sandvik “With COVID-19 leading to fewer people operating in the mining area to achieve the same output, digitalisation has become a vital efficiency mechanism for survival.”

As mining companies continue to work with specialised technology companies to integrate AI into their operations, other industries such as oil and gas, and energy are also using AI in their activities.

One of Australia’s leaders in emerging technology, Appello Software, believes AI has revolutionised the future of apps. AI is currently used to analyse behaviour to provide insight into the user. This leads to an increase in user engagement and resulting in personalised user experience.

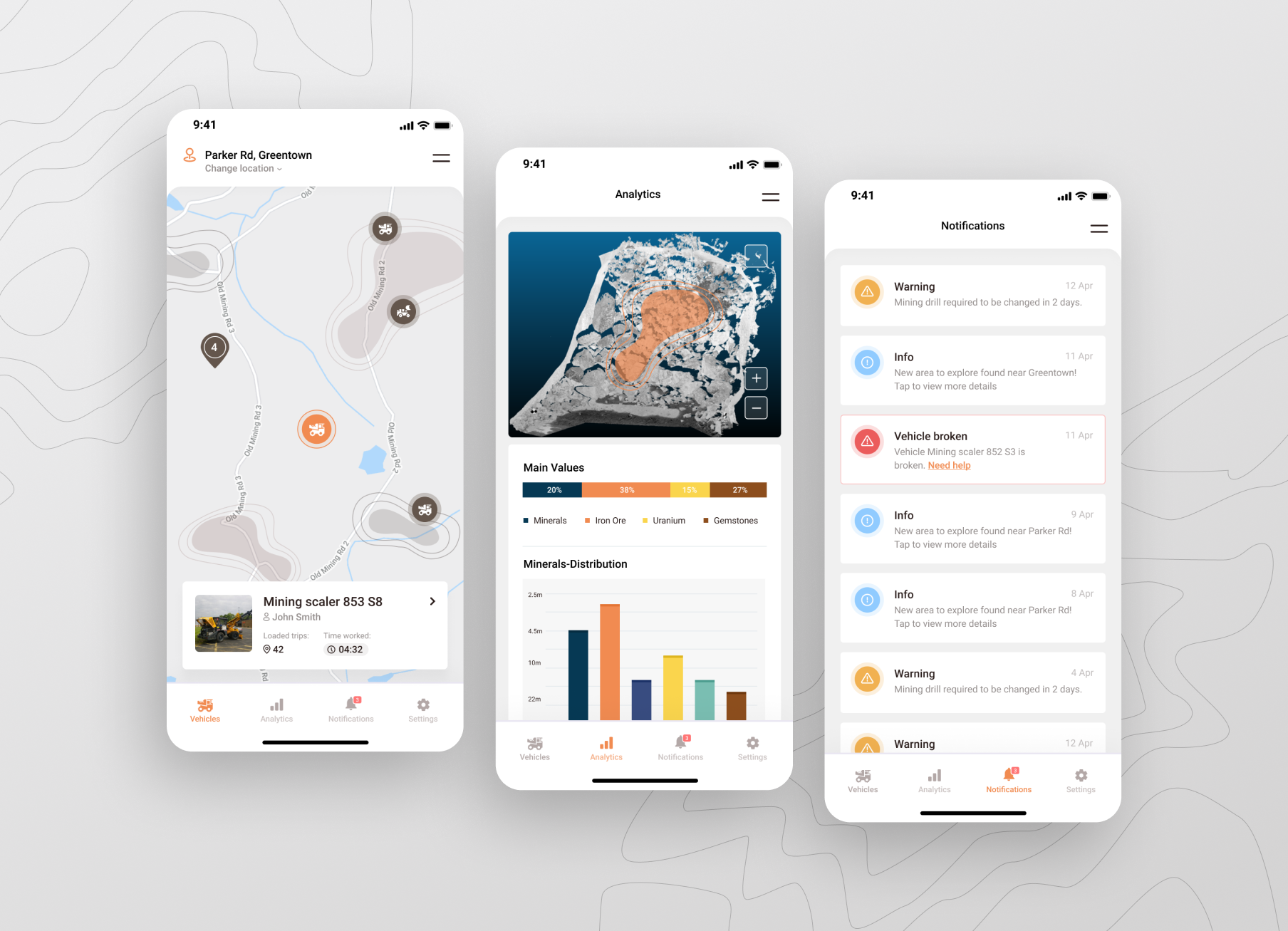

The image below is a project designed to be able to warn operators and maintenance crew of critical equipment downtime in advance. It also shows in real-time which employee is in each vehicle, the amount of hours they have worked, number of loaded trips etc. Techniques powered by AI enabling mining companies to become insight-driven enterprises.

Data Analytics

Constant use of data analytics can improve procurement, planning, operations and safety. Similarly, real-time analytics are used to predict maintenance, identify transport bottlenecks and enhance logistics. Thus, cutting costs and minimising downtime.

According to the Vice President of Shell, companies must recognise the benefits and opportunities that new technologies can bring. Digitalisation is the future of mining.

The Granny Smith Mine in Western Australia recently launched an integrated systems project. The company is digitising the mine to connect and coordinate its operators, workforce, equipment and mining activities in real-time. The project aims to create one of the most innovative, digitally connected mines in the world.

In conclusion, smart mining solutions reduce risks and create new opportunities for the tech-savvy generation to run more profitable operations. It is clear that the future of mining is here.